THECOMMERCIALGREENHOUSEGROWER

•

JANUARY 2017

10

•

IPM

NEWS

With the productionmodule

Dynamic, growers have been

promised the opportunity to

create their own choice of

“light recipes” – dedicated

combinations of

spectrum, intensity, timing,

uniformity and positioning to

meet individual needs.

With the right light it is

possible to steer specific

plant characteristics such

as compactness, colour

intensity and branch

development, resulting in the

optimal crop yield and

quality.

You can use it to grow an

ever-changing variety

of crops during the year, or to

investigate the effects of

different light recipes or a

pre-harvest treatment.

TheGreenPower production

moduleDynamic is designed

to enhance efficiency and

flexibility and offer the

research facilities for those

whowant to deepen their

knowledge about the impact

that light and light recipes

have on crop growth.

See our feature on vertical

farming on page 14.

leading international substrate groupKlasmann-Deilmannwho

have numerous sales andproduction companies inEurope,

Asia andAmericawill feature inHall 2.

All over theworld, the company’s growingmedia provides a

vital basis for plant growth, and for growers in the commercial-

horticulture sector.

The company say “Ourmost important rawmaterials includes

white andblack peat that we extract fromour own sites, as

well aswood fibre and green-waste compost that is produced

andprocessed in our own facilities”.

We are developing awide range of activities in the field of re-

newable energy and resources. In sodoing, we are placing our

confidence in the expertisewe have acquired overmany

decades inmanaging land on a large scale and in utilising

biomass, andwe are exploiting synergies between these differ-

ent operations.

Our ambitious sustainability strategy includes reporting in line

withGRI standards and a carbon footprint verified to ISO

14064 as the basis for our company’s future development. Our

goal is sustainable growth and lasting success in all of the

company’s activities. In this, our employees are a foundational

asset, playing a crucial role inmoving our organisation forward

aswe help them to excel.

Klasmann - DeilmannGmbH

Hall 2.0Booth 2D17

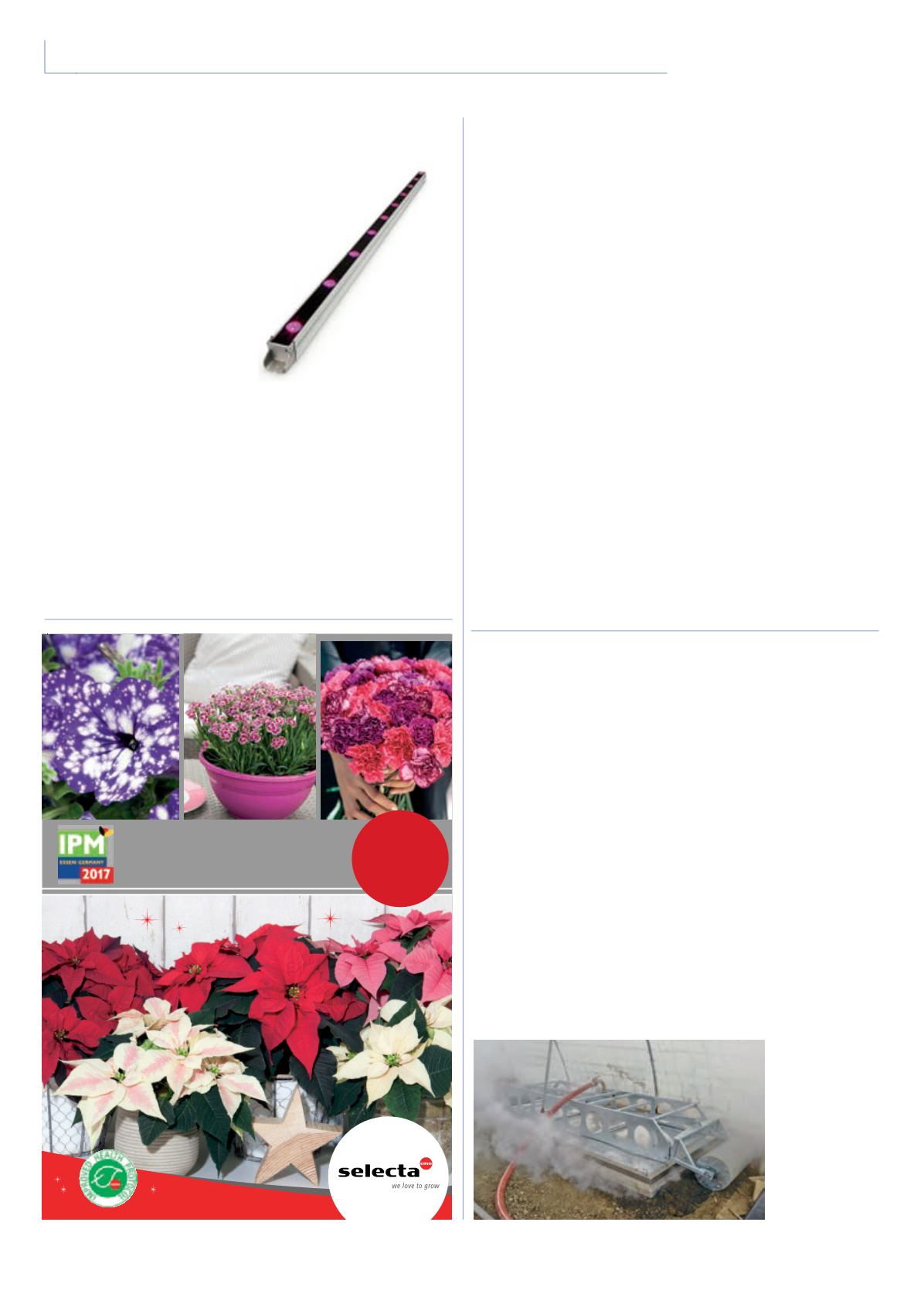

Getting steamed at Essen

Hall 3.0Booth 3B52

Gaps in effectiveness and increasing levels of resistance in

weeds anddiseases,

aswell as bans on and conditions governing the use of

pesticides have led to greater interest in steaming in all areas

of horticulture, both in greenhouses and the open.

Increasingly, modern, effective and energy-efficientmethods

are being applied and in greenhouses sheet steaming is being

replaced in some operations through the use of a steaming

hood for the process of sandwich-type steaming. This involves

disinfecting the ground to a depth of 25cm. Initial experiences

generated energy savings of 50%. Thismeans that surface

areas can be treated to a depth of 20-25cm at a heating oil

consumption rate starting at 0.7L perm², in order to

completely removeweeds and soil-borne diseases.

Semi-automatic and fully-automatic steaming in particular are

being used on open fields to combat neophytes such as,

JapaneseKnotweed andYellowNutsedge and have proved

successful.

Steam is also

proving

successful in

combating

weeds and soil

fatigue in

strawberry

cultures and

also in tree

nursery cultures.

D25 and

2allH

·a ittensioP

i e vmoC

tS

rsewo flutc· st lan ptop

f n ooitibihxr eut osi

omc

a-one.

lect e.s www

PhilipsGreenPower LED production

Hall 3.0Booth 3D81