10

THECOMMERCIAL GREENHOUSEGROWER • MARCH 2017

• SCREENS

breathablematerials are using screens for longer, and adopting

theNGG technique of venting above a closed screen at night

rather than screen gapping or increasing pipe temperature.”

In general UK growers seemmore cautious of NGG

techniques than their Dutch counterparts. “We know there are

growers in the north-east who are experimentingwithNGG

which includes venting above the open screen as the first

step in controlling humidity, although I don’t have any details

on numbers at themoment,” commentsDebbie. “Dutch

uptake has been driven through user groupswhich share their

progress and experience; at present UK growers are at the

early stages of adoption.”

She points out that screen opening and closing is linked to

different environmental influences anddesigned tomanage

energy, light levels and summer stress, for example. “TheNGG

approach of introducing a control system in the space above

the screen has been introduced as a concept, through the

AHDB fundedGrowSave project,” she adds.

“Some of themore recent environmental computer systems

have introducedmore sophisticated softwarewhich enables

further integration of various control systemswhile also

incorporating the latest thinking on some aspects of screen

management,” agreesMaxManning of Hortisystems. “Using

multiple horizontal screens gives growers the ability to get a

higher level of control and greater energy savings, perhaps by

mixing an energy screenwith a lighter shade screen. However,

multiple screens can increase shading from the screen

structure, evenwhen open, and increase capital costs.”

Consequently the use of additional screens needs careful cost

benefit analysis, but there are reports that someDutch growers

are nowmoving to triple screen systems.

“Multiple horizontal screens provide the opportunity to benefit

from greater energy saving by further reducing air leakage,

and their insulating effects,” explains Jon. “They also allow

improved tailoring of the environment beneath the screens

without compromising the evenness of that effect. Next

generation growing techniques requiremore screen operations

and keeping them closed for longer. In turn this requires

changes in venting considerations, such asmore aggressive

venting above a closed screen to enable humidity and

temperature control.”

“Double screen systems, such as a top shading system

and an energy system on the bottom, is amajor trend at the

moment according toAlweco, the screen supplier and partner

for BridgeGreenhouses. “There is no doubt about using

screens for energy saving, or cooling and shading, both can

nowbe done using a double screen system.”

Bridge’sDavidSummerfield adds, “Using double screens

gives a vast improvement in the control of the growing

environment, and energy saving, as there is no need to

compromise between ventilation, shading and energy saving

for example.”

The other main development is in the use of newmaterials

which allow screens to have different properties, such as

being fire retardant, transmitting different levels of humidity

andpreventing condensation. “Themain changewe have

seen over the last few years is the introduction of translucent

white plastic screen fabric replacing the aluminium based

shading,” commentsMax. “This has been led by Svensson’s

NewHarmonymaterial, which givesmuchmore diffuse

light penetration into the crop but at the expense of a slight

reduction in energy saving properties. It is interesting to note

that the flame retardant versions of thismaterial are significantly

more cost effective than aluminium based flame retardant

mercial GreenhouseGrower_92x131 (24-2) -drukklaar.indd 1

13-02-17 15:52

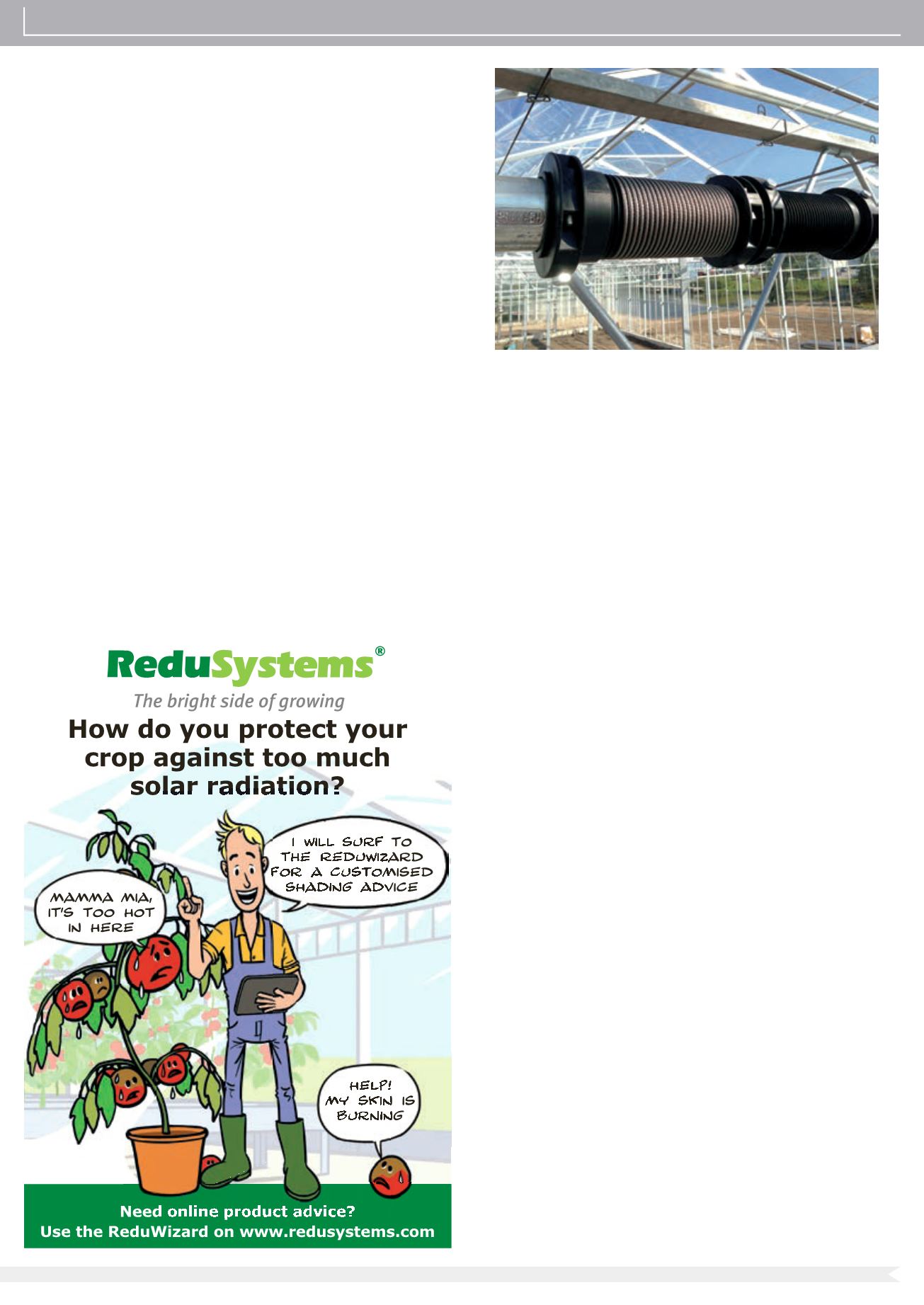

Alweco’snewUltraGroovecabledrum includes

grooveswhich reducewear on thecables.