•

LAMMA PREVIEW

•

THE

VEGETABLE

FARMER •

JANUARY 2017

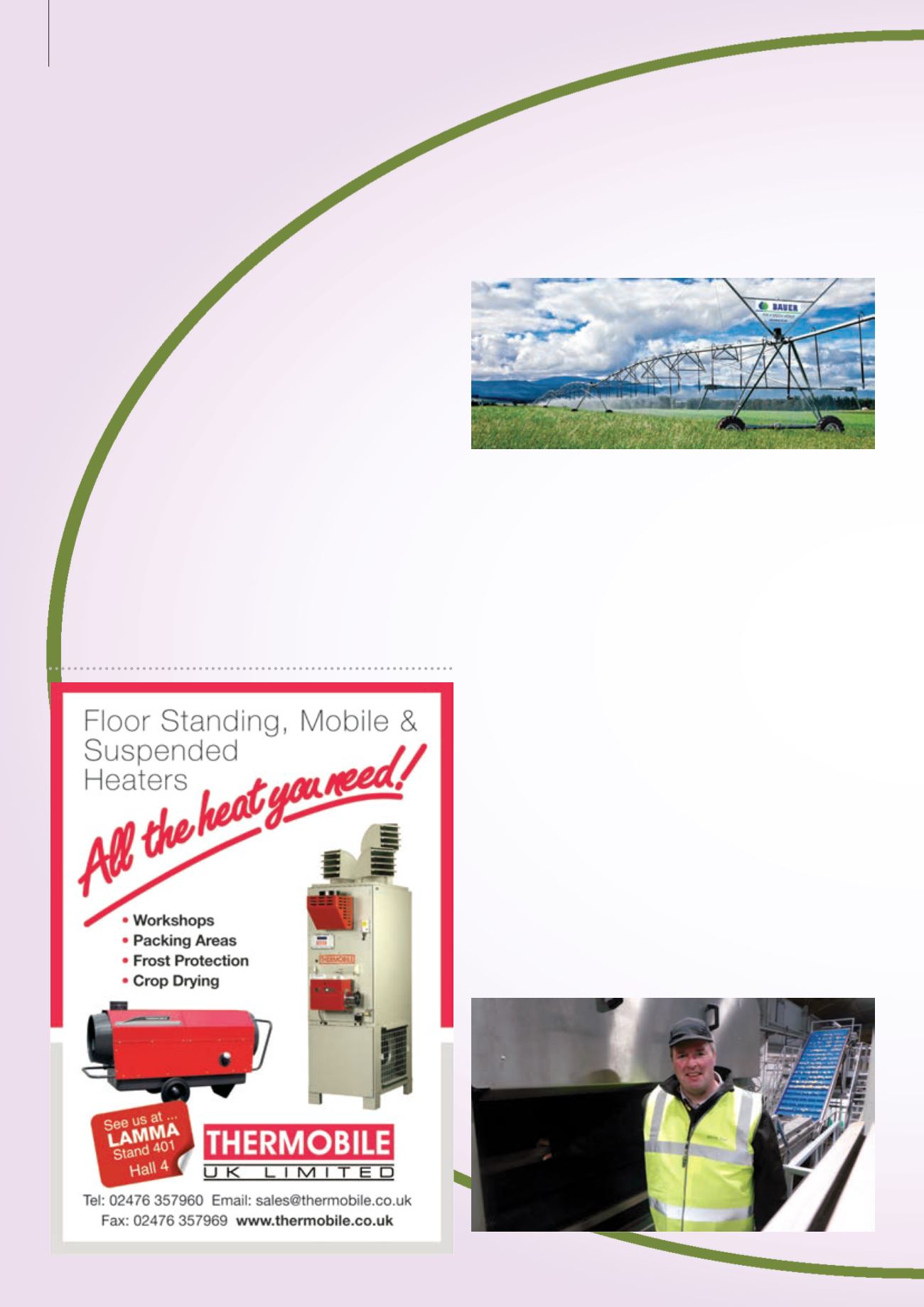

Bauer

will introduce its centre-

pivot irrigation system to UK

growers at LAMMA 2017 on

Stand G45

.

“We are a leading supplier of

mobile reel irrigators to growers

with our ProRain and Rainstar

systems,” says Adrian Tindall,

Bauer sales manager. “But we

believe there is amarket for a

modern centre-pivot systemwith

automated controls that keep the

manpower andmanagement

time needed to operate it to an

absoluteminimum.”

“Covering a large area from a

fixed point eliminates having to

keepmoving the irrigation

equipment, so the savings in

manpower are enormous,” points

out Adrian Tindall. “Also, moving

the irrigation boom by electric

motors rather than a water-

driven turbine, takes less energy

and applyingwater by low

pressure sprinklers rather than a

high pressure gun, makes more

efficient use of water through

reduced evaporation.”

The Bauer Centerstar 9000

irrigator operates with fixed or

wheeled pivot towers (the latter

enabling the system to be

relocated) that are constructed

from galvanised steel and scaled

to suit a number of span sections

covering up to 220ha in one go.

In Britain, the systems for up to

60ha and 150ha aremost

relevant, with a choice of nozzles

for the droppers providing

appropriate distribution and

droplet sizes for different crops.

External ball and socket joints

between each span structure and

the drive wheel towers allow

flexible articulation over surface

contours, while stability is

ensured by the generous 4.3m or

5.2mwheelbase of the two

inline drive wheels on each

tower.

18

Bauer launch Centerstar automatic pivot system

Haith celebrates 500th Rootveg polisher

More than 500

Haith

Rootveg

polisher machines have now been

produced,with one of the latest

Direct Drive Rootvegmodels

being sold as part of a £1.7m

washing, sorting and packing line

investment by Branston Potatoes

in Scotland.

Kevin Imrie is general manager

at Branston Scotland, where the

newHaithwashing, polishing,

grading and box/bag filling

system can accept potatoes at 50

tonnes per hour, and can grade

washed product at around

175,000 potatoes an hour.

Kevin said; “I looked at all the

major players when choosing a

new system and chose Haith

because I like the simplicity of

their designs. Simplicity translates

into easier maintenance and long

term reliability. Choosing Haith

was the no-risk option for me,

because of their experience and

proven track record.”

“This is the first time we have

used a polisher here,” he said,

“With the Haith Rootvegwe’re

definitely seeing the results, with

a brighter crop, and a superior

finish to the end-product. With

the new line, we’ve been able to

increase output and reduce

labour by 25%.”

Branston’s new potato grading

line also includes the latest

Newtec Celox optical sorter for

sizing and quality selection. This

machine is designed to reduce

manual handling, efficiently

remove quality defects and sort

the crop intomuchmore

accurate size bands ready for

packing.

Haith’s new advanced

Control+ Line Control System is

an in-house development,

designed to simplify

management. Control+ features

a 12 inch HMI touch screen from

where the whole line is

managed; run hours,

performance, maintenance,

scheduling and diagnostics are all

displayed. The HMI screen also

monitors Emergency Stop

buttons and Overload Trip

Identification. The system is

displayed in ‘work zones’,

allowing single zones to be

isolated for testing or

maintenance purposes.

The Haith Group designs

develops andmanufactures

machines for crop grading,

washing and polishing. Box and

bag tipping and filling.

Packhouse equipment, elevators

and conveyors, processing and

peeling equipment, bulk feeders,

inspection and sorting systems,

brassica handling, waste water

treatment and AD Feed Systems.

Haithwill be at LAMMA in

Hall

3A, Stand 3A171

.

Kevin Imrie of Branston Scotlandwith their Haith Rootveg polisher.